Micro-pollution removal

Powdered Activated Carbon (PAC) slurry preparation units for Micro-pollution removal.

Background

Man-made trace substances or micro-pollutants are substances which don’t break down easily, such as the remains of medicines, plant protection agents or industrial chemicals like e.g. PFAS.

Conventional wastewater treatment cannot adequately remove these trace substances from wastewater. So, they build up in watercourses and natural environments, where they cause a toxic or hormonal imbalance, thereby threatening ecosystems.

The metering of powdered activated carbon (PAC) in the last stage of municipal wastewater treatment systems has proven effective at eliminating such micro-pollutants.

Tomal offers several systems for dosing PAC depending on the facility and need:

- The quantity of water that needs to be treated

- The type of installation available

- The degree of precision required

- The degree of automation required

We can adapt our systems with the following combinations:

- PAC metered from a Big-Bag, for limited consumptions

- PAC metered from a Silo, for larger consumptions

- Volumetric dosing that offers a precision of 1-2%

- Gravimetric dosing for advanced precision (down to 0.2%) and exact recording of the quantity of PAC

We show below two examples of systems:

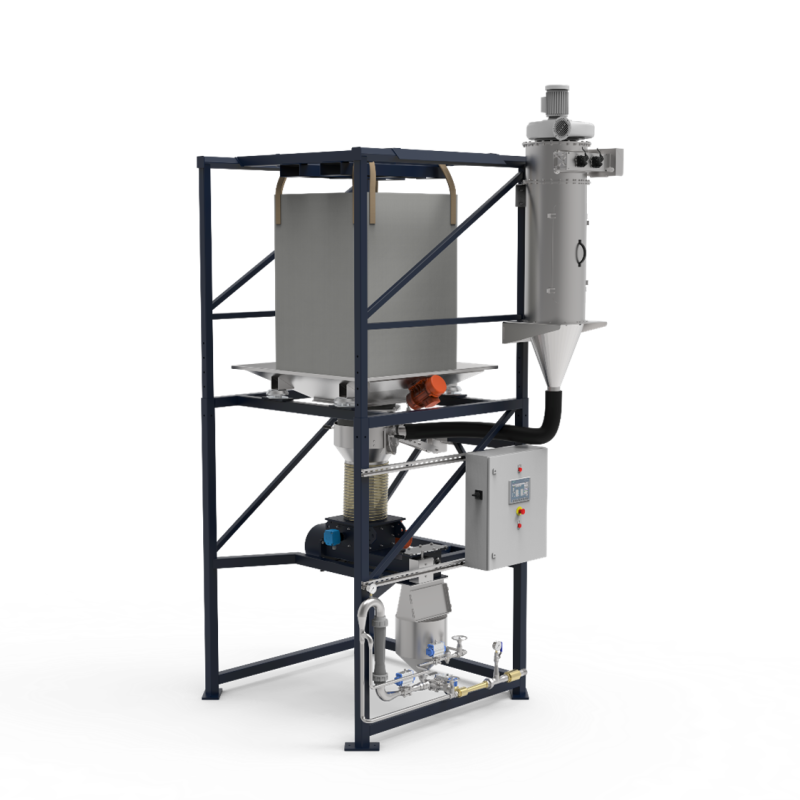

1. Metering of PAC from a Big-Bag with a volumetric system.

2. Gravimetric metering of PAC from a silo.

These two examples illustrate the advantages of each system.

Example 1

Volumetric metering of PAC from a Big-Bag

Metering of PAC from a Big-Bag with a Tomal multiscrew feeder:

This solution will be chosen for a slurry preparation capacity of up to 50 kg/h PAC, that is equivalent to approximately one Big-Bag per day. For higher consumptions the installation of a silo could be considered, for optimising the handling of the material.

The volumetric dosing technology allows to reach a precision of 1-2% at constant PAC bulk-density

Functional description

The Big-Bag is lifted with a forklift and positioned on a Big-Bag discharger frame.

The Big-Bag is opened at the bottom, and the outlet spout is untied and placed into the powder hopper.

The multiscrew feeder meters the PAC simultaneously with the preparation water into the wetting cone. The transfer of the final PAC slurry is done with the Venturi water ejector to the dosing point at max 1 bar back pressure.

Features

- Tomal-unique multiscrew feeder allows a volumetric dosing precision of 1-2%

- Dust free operation for a safe working environment thanks to the hygienic clamp

- Efficient wetting cone with venturi system

- Possibility to add load cells for gravimetric dosing and live-recording of the PAC consumption

- Modular system with recommended dosing range up to 50 kg/h PAC

- Turnkey delivery including control cabinet with electrical installation, and commissioning

- Available with integrated lifting hoist to the Big-Bag support

- CE-marking according to the Machine Directive 2014/34/EC

Example 2

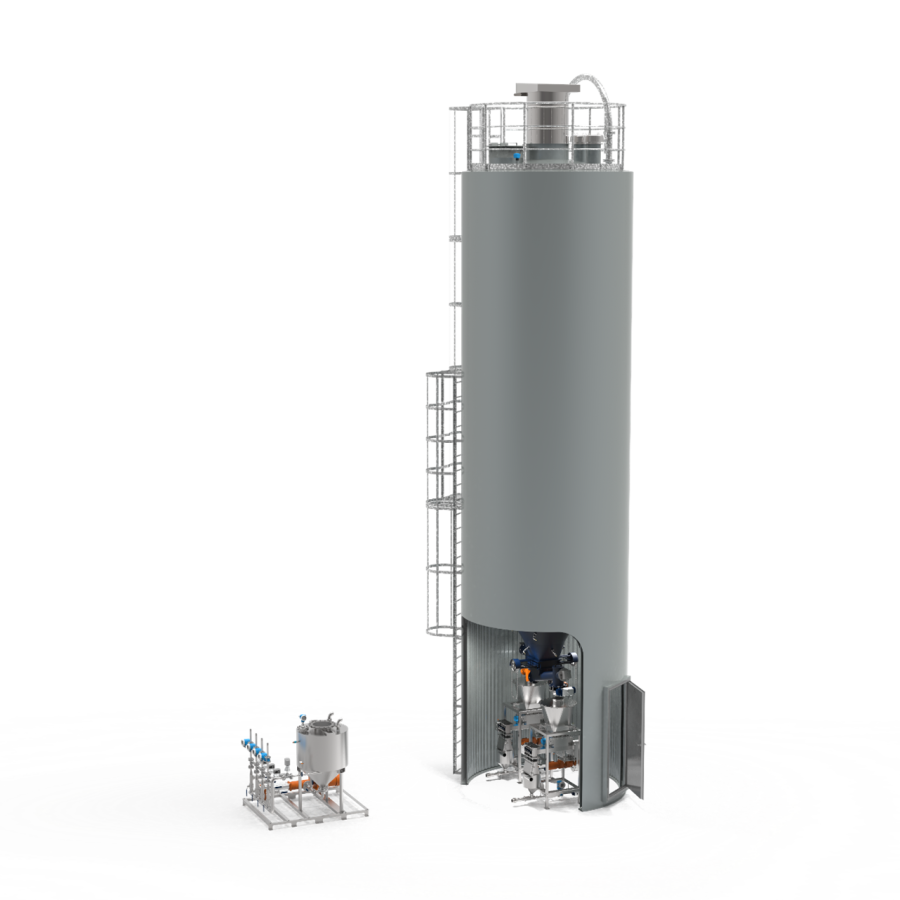

Gravimetric metering of PAC from a silo

Dosing of PAC directly from a silo with a Tomal multiscrew feeder coupled to a weighing hopper. The slurry created will be dosed form a buffer tank and will be recirculated to avoid any sedimentation.

This solution could be chosen

• At larger wastewater treatment plants

• When a high-level of automation is required

With a buffer tank the slurry output capacity is up to 10m3/h and approximately 5% in concentration.

This system is gravimetric which means a high degree of precision of the PAC dosing can be achieved, typically 0.2%. It allows to monitor the exact amount of PAC that is consumed. This system is branded under the brandname DULCOPAC.

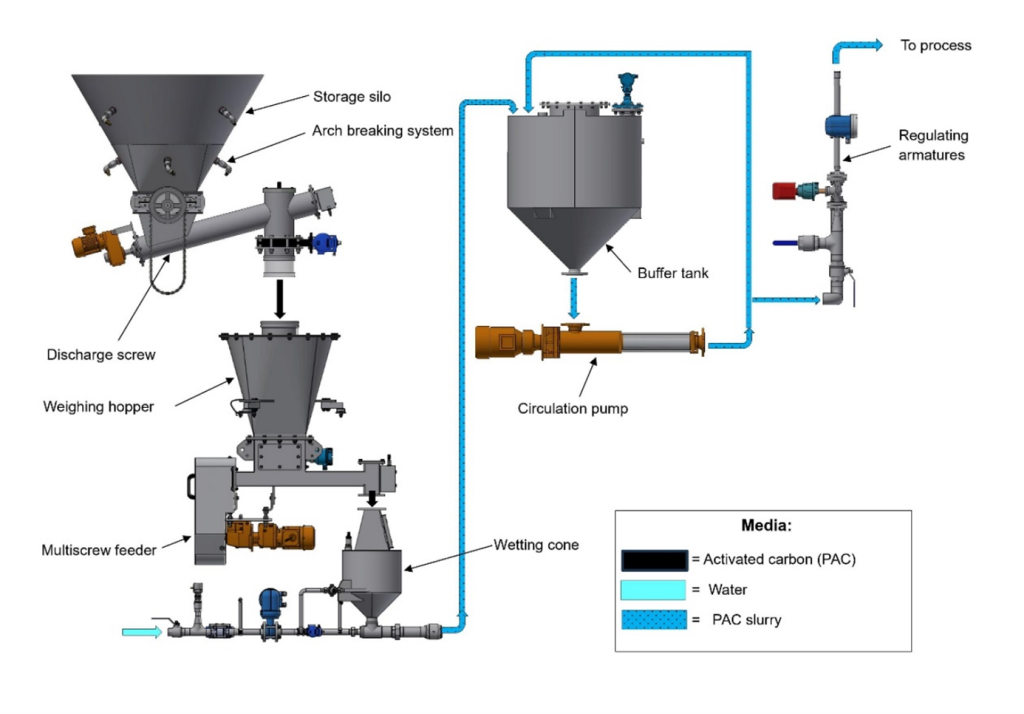

Functional description

DULCOPAC consists of a gravimetric feeding system mounted under a storage silo.

The PAC is fed gravimetrically into a wetting cone where it is mixed with water and conveyed to a buffer tank from which the slurry is pumped to the dosing points.

At low level, the weighing hopper is refilled with PAC from the storage silo with the discharge screw. Eventual arch buildings will be broken by Tomal arch-breaking system.

A shut-off valve prevents additional PAC from falling into the hopper after stop of the discharge screw.

The unique Tomal multicrew feeder feeds PAC into the wetting cone. The Tomal feeder, in combination with a gravimetric loss-in-weight system guarantees an optimal feeding accuracy.

In the wetting cone the PAC is entirely wetted, in a controlled manner, with minimal amount of dilution water. The water flow is measured with a flow meter and the adequate amount of PAC is added, regulated by the loss-in-weight-system, to obtain a constant slurry concentration.

The slurry created is further conveyed with a water eductor to a buffer tank.

Finally, the slurry is pumped in a recirculation pipe to multiple injection points from where it can be dosed into the water to be treated for micro-pollution. The dosing of slurry is accurately controlled by a flow meter, and a regulating valve mounted on a distribution skid.

The dosing rate from the system can be controlled based on the water flow into the contact basin.

The unused slurry is conveyed back to the buffer tank in the recirculation pipe, The continuous recirculation ensures that the slurry is in constant motion to minimize the risk of sedimentation.

The system can be delivered in single or dual design. The silo can be mounted at distance from the distribution skid. The system can generally be adapted to suit specific customer requests.

Turnkey delivery including control cabinet with electrical installation, erection, and commissioning.

CE-marking according to the Machine Directive 2014/34/EC.

Features

- Accurate slurry preparation with constant concentration

- Dust free operation

- Turnkey-system incl. storage silo up to 200m³

- Arch-breaking system for minimal risk of fluidization

- Dual silo emptying for full redundancy

- Modular system with dosing rate 4-400 kg PAC/h

- Output capacity up to 10m³/h slurry delivered to multiple injection points

- Delivered with electrical cabinet and PLC system compatible with multiple BUS protocols, or as a cabinet-free option for integration

- Tomal-unique multiscrew feeder in combination with gravimetric loss in weight system ensures exceptional accuracy